Meine Kunden müssen nach Corona die Lieferantenkette und die Produktion an die Situation anpassen. Beispielsweise Nicht-Produktionsmaterial, Supply-Chain und Kostensenkung optimieren, Warenlager und Durchlaufzeiten reduzieren, Qualität und EBITA verbessern.

Spätestens jetzt fragen Sie sich zu Recht, was qualifiziert mich dazu diese Empfehlung auszusprechen.

Ich bin Autor des Buches “Effective Cost Cutting in Asia” veröffentlicht bei Springer, sowie dem Diplomatic Council-Buch “Management in China”.

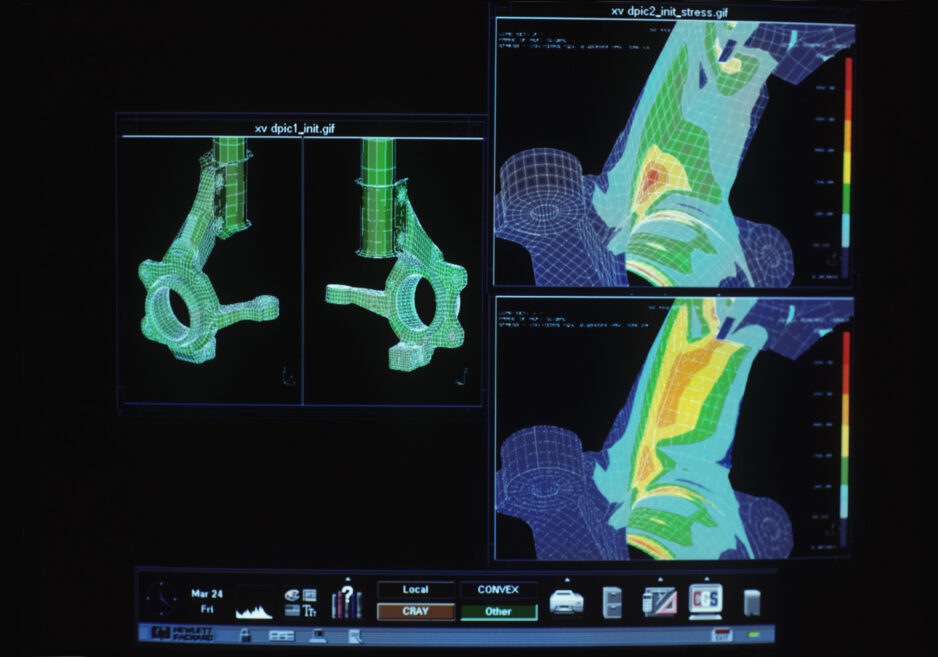

Seit über 20 Jahren unterstützte ich als Berater und Coach Unternehmen in den Bereichen Qualitätssicherung, Einkauf und Verhandlungsführung in Asien – hauptsächlich in den Bereichen Automobil, Maschinenbau, Elektrik und Elektronik.

Meine fachliche Expertise in Japan, Korea, China, Malaysia, Vietnam und Indien sowie das Eintauchen in die asiatische Kultur und das chinesische Lebensgefühl machen meine Stärken aus.

Wie läuft das praktisch bei mir ab?

Für Sie nehme ich ein Beispiel heraus wie ich Unternehmen als Interim Manager zu mehr und schnellerem Erfolg führen kann:

Der globale Einkaufschef eines deutschen Automobilzulieferers vermittelte mich als Interim-Einkaufsleiter in das chinesische Hauptwerk in Shanghai. Ich ersetzte den wegen Korruption entlassenen chinesischen Einkaufsdirektor.

Zu Mandatsbeginn war die Finanzlage des Zulieferers angespannt. Zudem wurde der Interim Manager mit der Tatsache konfrontiert, dass auch der jetzige chinesische General Manager gekündigt wurde, aber bis zur Übergabe noch im Unternehmen bleibt. Noch herausfordernder wurde das Mandat durch weitere Personalprobleme. Einige Mitarbeiter im Einkauf hatten sich krankgemeldet. Die Mitarbeiterin, die allein das Nicht-Produktionsmaterial (NPM) betreute, war in Mutterschutz.

Im ersten Schritt machte ich mich daran, die Prozesse für Nicht-Produktionsmaterial neu aufzustellen. Ich eruierte den Bedarf der jeweiligen NPM-Verantwortlichen und entwickelte einen Workflow von Anfrage bis Eintrag in das ERP-System. Zudem legte ich ein RASIC mit Abteilungen und Namen fest. Dieser Planung wurde anschließend abgearbeitet.

Zudem unterstellte ich alle Ausgaben meinem Genehmigungsvorbehalt. Danach machte ich mich daran, neue Verträge zu verhandeln. Das betraf unter anderen die Bereiche Werkzeugbauer, Maschinenlieferanten, Umweltauditoren, Abfallbeseitigungsfirmen, Transportfirmen, Hotels und mehr.

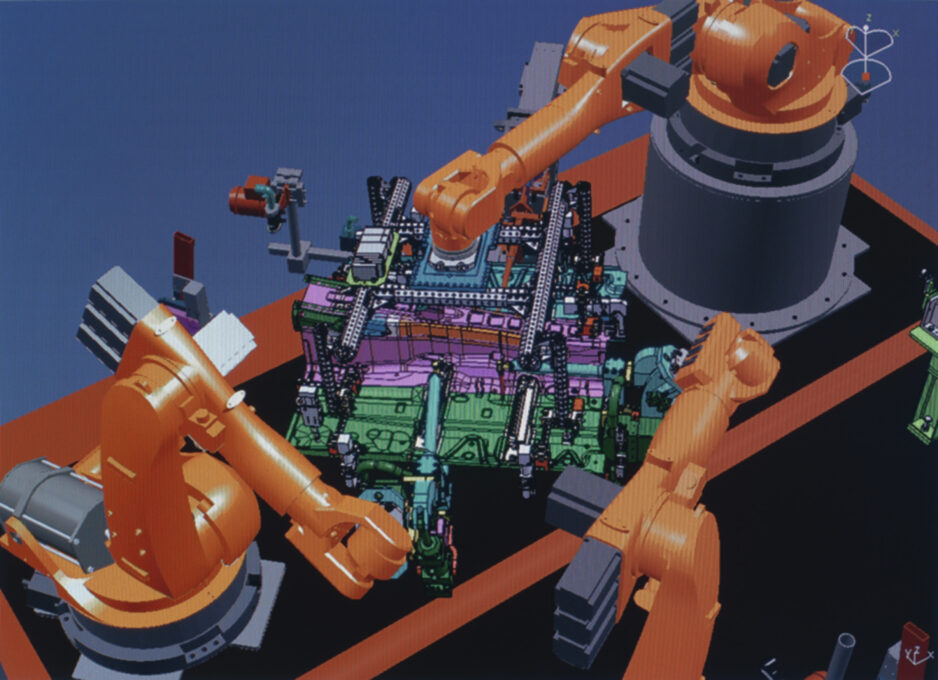

Im nächsten Schritt löste ich teure Zwischenlager und Verträge mit teuren Transportunternehmen auf, die vom ehemaligen Einkaufsdirektor abgeschlossen und vom General Manager genehmigt worden waren. Ziel war es, zukünftig anstatt vieler lokaler Transportfirmen nur noch eine internationale Spedition zu beauftragen. Wichtig hierbei war es, dass diese alle Transportwege bespielen sollte: Land, Schiene, Luft und Wasser. Hierzu initiierte ich ein Benchmark und verhandelte mit zwei Firmen die Konditionen.

Auch Zwischenhändler für Elektronikbauteile sollten zukünftig weitgehend vermieden werden. Diese übernahmen zwar die Konsignationslager und lieferten Einzelteile recht pünktlich, jedoch waren die Teile viel teurer als bei einem Direkteinkauf. Mein Team und ich verhandelte hart über die hohen Mindestbestellmengen, bis ein Vertragsabschluss erzielt wurde.

Im weiteren Verlauf veränderte ich das Projektmanagement im Unternehmen. Nunmehr ist der Einkauf in jeder Entwicklungsstufe frühzeitig eingebunden. Auf diese Weise ist sichergestellt, mit gut ausgewählten Lieferanten kostengünstig produzieren zu können.

An meinem letzten Tag im Unternehmen unterzeichnete ich zwei Verträge mit Speditionsunternehmen. Anschließend übergab ich die Abteilung an den neuen chinesischen Einkaufsleiter. Eine Herausforderung blieb bestehen: die Zusammenführung aller Abteilungen zu einem Team unter Berücksichtigung der KPI-Vorgaben und Compliance-Kontrollen „von ganz oben“.

Die Auswahlmethodik der Produktions- und NPM-Lieferanten basiert in China traditionell auf Beziehungsebene, nicht auf Preis-, Qualitäts- oder Terminebene. Dies wird auch der neue chinesische Einkaufsleiter nicht ändern wollen. Daher ist ein sehr strenges und permanentes Compliance- Controlling vom Einkauf im HQ oder vom neuen deutschen General Manager in China unerlässlich.

Schreiben Sie mir vertraulich, wo externe Unterstützung für Sie Sinn machen könnte.

Ich bin mit meinem Interim Management Service da, um Sie zu entlasten – versprochen.