Tooling Costs (Direct Payment)

Tooling cost subsidy and spare parts: Up to 80% of the tooling costs to be paid in advance.

Tooling cost supplier: 100% lumpsum payment to the supplier.

Costs for tooling changes: 100% lumpsum payment to the supplier. Tooling costs include additional costs, tryout/audits. The costs for maintenance are included in the piece price. Amortization is included in the piece price as well. Fixtures, gages and machines are amortized in piece price, for example: buying or production costs, interest, and maintenance.

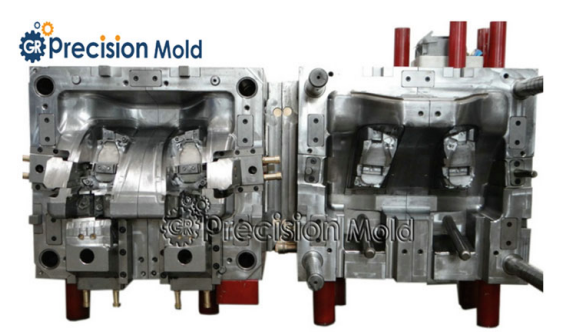

Die Casting and Plastic Injection Moulds

The cost calculation for the production of an injection mould is composed by:

- Design

- programming

- Tool structure (mechanical rough machining)

- Mechanical machining of inserts and sliders

- Hardening (through-hardening or nitriding)

- Mechanical finishing of inserts and slides

- Adjustment at the injection moulding machine

- Quality acceptance (FMEA, APQP)

- EMPB (Initial sample test report)

How to Reduce Costs for the Production of an Injection Mould?

First, the economic rationality of the design is very important to the cost control of the mold. Therefore, managers should strengthen the training of designers to enhance their ability and designing level. Second, effective control of the factory’s processing, improve workers efficiency and quality of work, hold morning meetings to arrange their work reasonably. Third, material cost accounts for 30% in mold production. Therefore, injection mold materials should be selected correctly, and the planned material should be coordinated with the requirements of mold life. Fourth, the control of mold cost is proportional to the quality and delivery date. If the mold quality is in place at one time, the delivery time will be shortened with less modification, so that the manufacturing cost will be reduced accordingly (Fig. 6.27).

In detail, the following parts for the tool must be manufactured and calculated (example for plastic injection):

- Clamping plate

- Ejector package

- Mould plate

- Intermediate mould plate

- Guide columns

- Guide bushings

- Guide pins

- Hot runner manifold block

- Hydraulic cylinder

- Ledge

- Heat protection plate