Karlheinz Zuerl, CEO of the German Technology & Engineering Corporation, stated: “While Europe is still focused on Industry 4.0, Asia is already gearing up for Industry 5.0, which emphasizes autonomy over mere connectivity.”

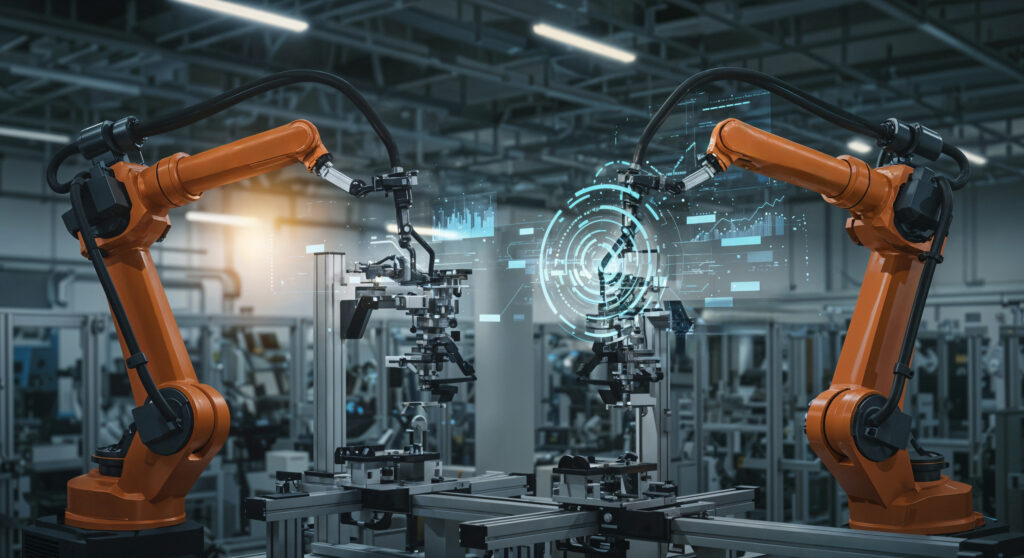

Berlin/Shanghai, 29 April 2025 – Karlheinz Zuerl, CEO of the German Technology & Engineering Corporation (GTEC), is confident that autonomous factories are rapidly emerging in Asia and will gradually make their way to Europe in the coming years, albeit with some delay. He commented: “While Europe takes pride in its achievements with Industry 4.0, Asia has already advanced to Industry 5.0.” By this, Zuerl refers to production facilities completely devoid of human workers, where only robots operate. These “ghost factories” are made possible through the integration of advanced computing, networking, artificial intelligence, robotics, and innovative manufacturing processes.

“Europe is sugarcoating Industry 4.0”

Karlheinz Zuerl refers to the latest “World Robotics Report” by the International Federation of Robotics (IFR), which contains figures from 2023. According to the report, there are now almost 4.3 million industrial robots working in factories worldwide — a historic high. Over 540,000 new robots were installed in 2023, more than half of which (51 per cent) were installed in China. Europe accounted for just 17 per cent of all new installations. Germany, the largest European market for industrial robots according to the IFR, recorded growth of just 7 per cent compared to the previous year.

According to the CEO of the German Technology & Engineering Corporation, “in Europe, and particularly in Germany, there is a tendency to exaggerate the significance of Industry 4.0 with meaningless figures.” For instance, studies by the industry associations Bitkom and VDMA claim that approximately 65 per cent of companies in Germany utilize Industry 4.0 technologies. “That sounds impressive, but it’s completely irrelevant because it includes every device with a Wi-Fi connection,” said Karlheinz Zuerl.

BMW is at 4.0, Tesla is at 5.0, and China is above 4.5

It is telling that the BMW plant in Dingolfing is considered the pride of the German automotive industry because, since 2024, fully manufactured cars drive themselves to quality control. “However, this only works with special external sensors along the route and does not mean that the vehicles themselves have autonomous driving capabilities,” said Karlheinz Zuerl. “It’s not comparable to the Tesla factory in Fremont, California, where the cars travel from the production line to the logistics area entirely autonomously, without any external support. BMW is at level 4.0, Tesla is at 5.0, and many Chinese manufacturers are already at 4.5 or better in this scenario.”

GTEC boss Karlheinz Zuerl is concerned that the gap will continue to widen to Germany’s disadvantage. He points out that the VDMA is forecasting a weak year for robot installations in 2025. However, according to the association, there is hope for a slight recovery in 2026.

Surge in Digital Twin Adoption in Asia

“In Asia, we are witnessing a surge in the adoption of ‘Autonomous Production Twins’ (APT) or digital twins in the manufacturing industry, aimed at autonomously monitoring, controlling, and optimizing production processes,” reported Karlheinz Zuerl. An APT combines real-time data, artificial intelligence, and advanced networking to create a virtual representation of the production system that can make decisions and adjust processes on its own. “An autonomous production twin can actively control manufacturing processes and respond to unforeseen events, such as rescheduling in the event of material shortages,” explained the GTEC CEO, highlighting how this has become a daily reality in more and more factories across Asia.

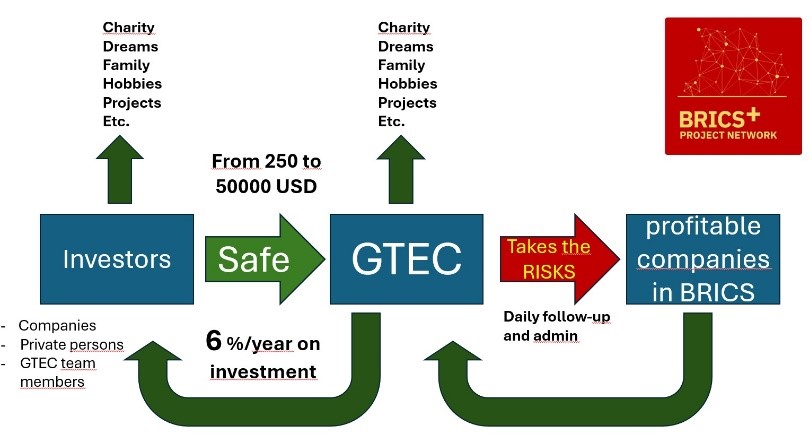

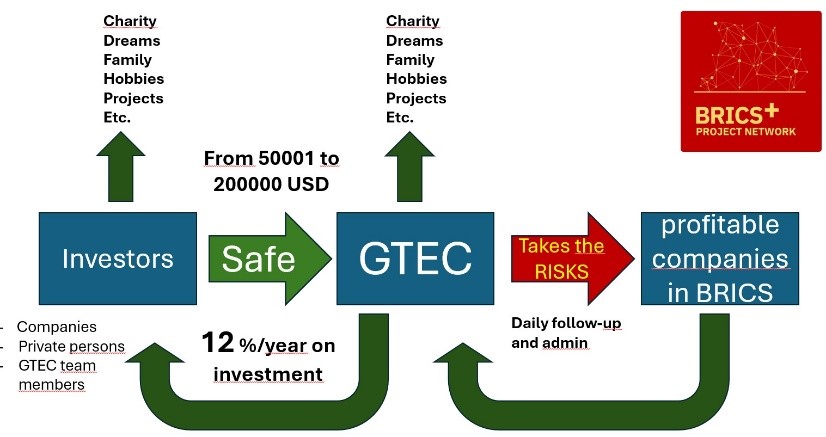

“Unmanned factories can reduce operating costs by up to 25 per cent, increase productivity by up to 30 per cent, and cut error rates by up to 40 per cent,” said Karlheinz Zuerl, highlighting the competitive advantage of Asian Industry 5.0 production. The GTEC CEO offers this advice to Western industrial companies: “Set up an autonomous factory in Asia, learn how it works, and then adopt this concept for your European plants.” This approach is suitable not only for car manufacturers, but also for many machine and plant manufacturers. Although sensor technology, software, and infrastructure account for around a third of the total costs of setting up an autonomous factory, Karlheinz Zuerl said that the higher investment pays for itself in the first year of operation, thanks to the significantly lower wage bill alone. Added to this are greater flexibility in reacting to market changes and a higher quality standard, which reduces rework costs and increases customer satisfaction.

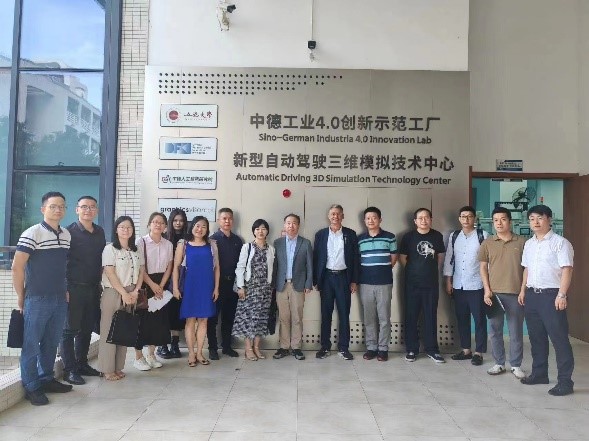

GTEC (https://gtec.asia) helps Western industrial companies to overcome challenges in Asia. The focus is on business development, the establishment and expansion of branches and production facilities, as well as restructuring and turnaround measures to bring automotive suppliers and mechanical engineering companies in critical phases back into the profit zone. Under the direction of CEO Karlheinz Zuerl, a team of consultants, experts, and interim managers is on hand to work on-site with the client if necessary. The CEO himself is available for tasks as an interim general manager and for executive consulting. GTEC’s list of references includes corporations such as BMW, Bosch, General Motors and Siemens, large medium-sized companies such as Hella, Schaeffler, Valeo and ZF, as well as smaller medium-sized companies that are less well known but are operating all the more

Weitere Informationen: GTEC, Web: https://gtec.asia,

E-Mail: contact@gtec.asia

PR-Agentur: euromarcom public relations,

E-Mail: team@euromarcom.de, Internet: www.euromarcom.de,

www.facebook.com/euromarcom (like if you like-:)

Experts in the Automotive Industry Asia

You need one, but don`t want to hire one permanently?

Our solution: To rent our experts

- On pay-to-use basis

- Completely flexible

- Contract can be cancelled any time

Clearly represented reports and dashboards inclusive!